The Wheel Profile Measurement System uses multiple lasers and multiple high speed digital cameras embedded under the track to capture a profile of every wheel that passes over it. IEM supplies a complete line of automated wheel inspection stations ranging

from slow speed shop systems to high speed mainline applications. Customers are using WPMS data in yard applications to route cars with defective wheels to trouble tracks, locomotive applications to conduct wheel diameter measurement comparisons,

and in transit applications to track wheel wear and do predictive, condition-based maintenance.

Product Overview

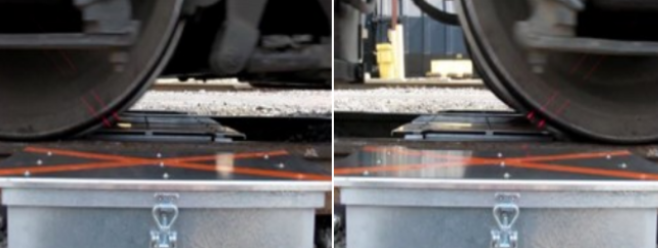

Laser Projection Measurement: The WPMS-1800 uses dual-sided multi-line lasers and high-speed digital cameras embedded under the track to capture a profile of every wheel that passes over it.

Highly Accurate: WPMS-1800 takes up to three separate measurements simultaneously, providing the most accurate wheel profile measurement possible.

High-Speed & Heavy Freight: The Model 1800 is housed inside a temperature controlled, structurally heated steel chassis called an Instrumented Tie Box.

Easy Installation: As a prefabricated unit, the ITB minimizes installation time and cost; the major construction component of the installation is as simple as replacing a tie or sleeper.

Product Features

Competitive Advantages

-

01 ITB Provides Durable Housing

-

02 Enhanced Expansion Capabilities

-

03 Highly-Accurate and Repeatable

Key Features & Details

IEM’s WPMS-1800 utilizes redundancy in the design and assembly of multiple lasers and cameras to provide our patented “True-Vision” 3D Optical Metrology for calculating the wheel measurement parameters. For each wheel, capability to

measure or detect includes time/ date, axle number, train speed, wheel 2D profile, wheel diameter, flange height, flange width, flange angle, rim thickness, hollow tread, tread buildup, and rim rollover.

|

Structural Load |

Power Requirements |

Measurements Taken |

Resolution |

|

Up to 50 Tons |

Max 25 kVA |

Wheel Diameter and Profile, Back-to-Back Measurement |

0.125 mm |

|

Accuracy |

Acceptable Train Speeds |

IP Rating |

Temperature Range |

|

+/- 1% |

0—350 km/hr |

IP65 |

-30°C—+50°C |

Additional Benefits/Factors

Shipped with the Instrumented Tie Box is an assortment of attachments which transform the ITB from a simple steel “Sleeper” to the core structure of a rugged measurement system. These attachments include equipment enclosures for the measurement

devices, as well as environmental conditioning units like blower and exhaust units. There is even an attachment that provides protection from dragging equipment.

WPMS-1800 capturing multiple area scans in the “5 o’clock” and “7 o’clock” segments of the wheel, guaranteeing that all wheels are measured

WPMS-1800 capturing multiple area scans in the “5 o’clock” and “7 o’clock” segments of the wheel, guaranteeing that all wheels are measured

Product Overview

Efficient & Effective: The WPMS-1600 works by capturing multiple images of the front and back profiles of each wheel.

Highest Resolution: IEM’s line of WPMS products have the highest resolution of any profile system on the market today, with measurement repeatability in the 0.1mm range.

Defect Detection: The high-resolution cameras display every variation around the circumference of the wheel as a result of normal wear.

Custom Measurement Reports: Once the basic profile has been captured, any number of standard or custom measurements can be generated, including flange thickness, flange height, flange angle, rim

thickness, back-to-back, and wheel diameter.

Product Features

Competitive Advantages

-

01 Detailed Images to a Single Pixel

-

02 Easily Installed and Upgraded

-

03 Built Durably for 24/7 Use

Key Features & Details

IEM’s WPMS-1600 comes equipped with an axle counter as well as a time and date stamp. It also includes an AEI Reader alongside an Analytic Software Package. IEM’s Remote Support Package ensure that you have complete access to IEM’s suite

of engineering and IT support; we turn your challenges into solutions, providing quality service guaranteed.

|

Structural Load |

Power Requirements |

Measurements Taken |

Resolution |

|

Up to 50 Tons |

25 kVA |

Wheel Diameter and Profile, Flange Height, Width, and Angle |

0.125 mm |

|

Accuracy |

Acceptable Train Speeds |

IP Rating |

Temperature Range |

|

+/- 1% |

0—350 km/hr |

IP65 |

-30°C—+50°C |

Additional Benefits/Factors

The WPMS-1600 is easy to install and maintain: the system is housed in a fully sealed Instrumental Tie Box (ITB) providing protection from the environment. WPMS-1600 is fully compatible with IEM’s complete line of WISE Wayside Equipment, making

it easy to upgrade and fully supported. Additional WISE systems include the Brake Pad Measurement System (BPMS), the Truck Component Inspection System (TCIS), and Optical Wheel Flaw (OWF).

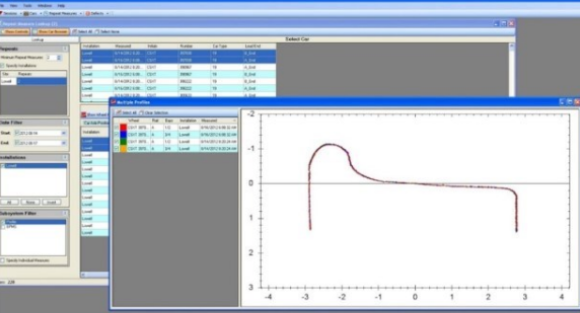

WISETM WHEELTRACK software displaying WPMS-1600 measurements and depicting wheel profile

WISETM WHEELTRACK software displaying WPMS-1600 measurements and depicting wheel profile

Product Overview

High Percentage Detection: WPMS-1400 has a high percent detection rate, meaning flats touching the rail will be detected.

In-Shop System: Sensors are designed to respond only to mechanical impacts, so there is a very low false alarm rate.

Weather-Proof: The system will be unaffected by natural variables or possible electrical interference.

Fastest to Install: The WPMS-1400 is quick and easy to install, as well as fully customizable, and measures all wheel sizes and types ranging from large locomotive wheels to smaller vehicles. P

Product Features

Competitive Advantages

-

01 WISE® System Integrations

-

02 Low Speed Detection for Rail Yards

-

03 Accurate Digital Wheel Profile Results

Product Overview

Low Cost & Efficient: IEM’s WPMS-1100 is an answer to the need for low-cost, easy to install wheel measurement systems for dedicated fleets.

No Welding Required: WPMS-1100 consists of a bolt-on fixture that takes a single field-side scan of the entire wheel profile.

Automatic Report Generation: IEM’s WPMS-1100 comes equipped with an axle counter, time and date stamp, and an AEI Reader alongside an Analytic Software Package.

Remote Monitoring: IEM’s Remote Support Package ensure that you have complete access to IEM’s suite of engineering and IT support; we turn your challenges into solutions, providing quality

service guaranteed.

Product Features

Competitive Advantages

-

01 WISE® System Integrations

-

02 Lowest Cost Profile System on the Market

-

03 Measures Flange Height & Thickness